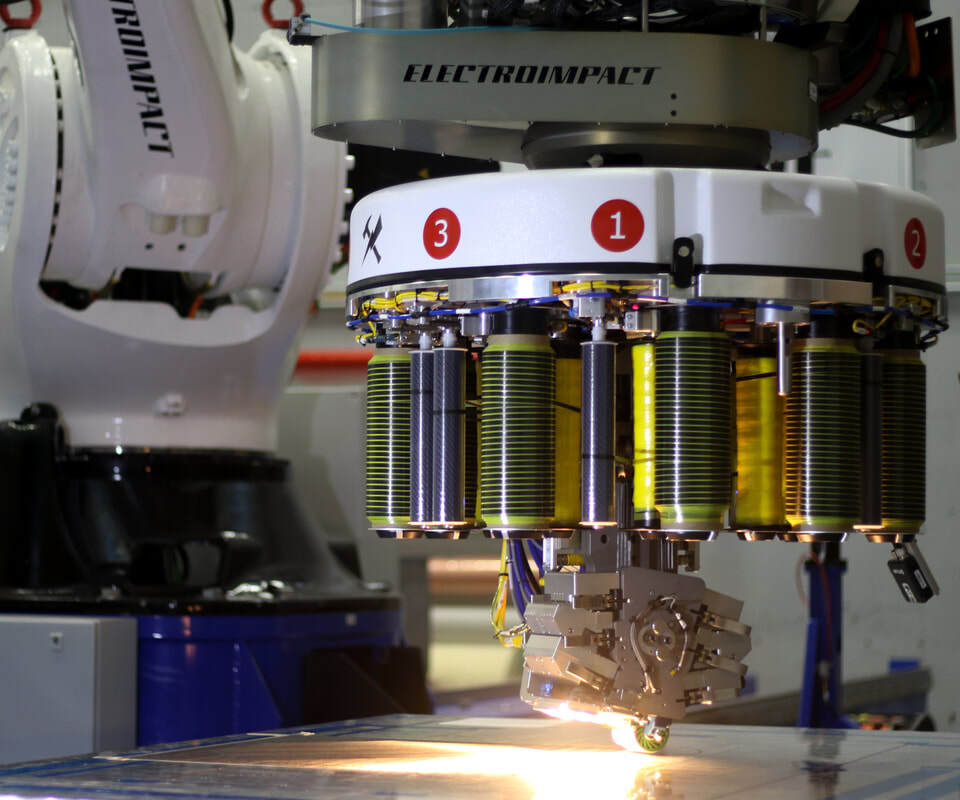

An Automated Fiber Placement (AFP) head is a piece of aerospace manufacturing equipment used to deposit uncured composites onto a mold. The AFP heads carry spools of material ranging from 1/8” wide to 1/2” wide tapes. Each head contains its own electrical, pneumatic and controls system and can be mounted to a gantry machine or industrial robot arm.

I worked to design and improve mechanical systems on the creel and the process ends of these end effectors. I also worked to support legacy AFP heads used in production facilities around the world.

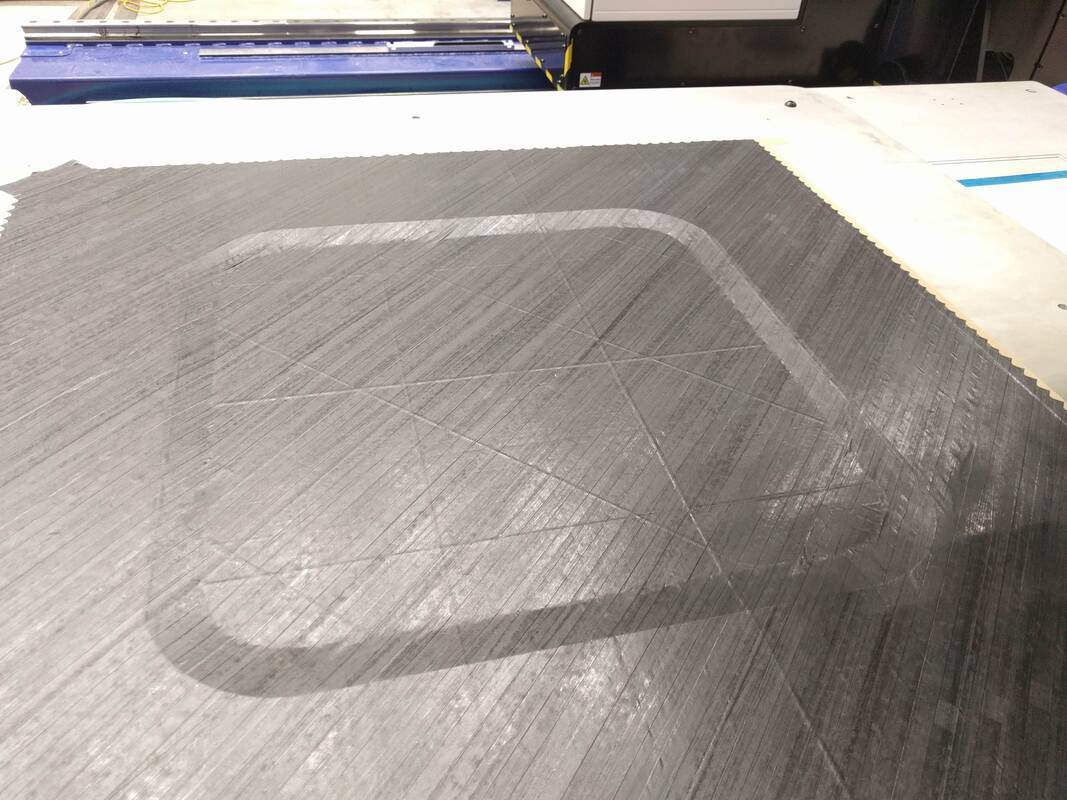

Large gantry AFP machine

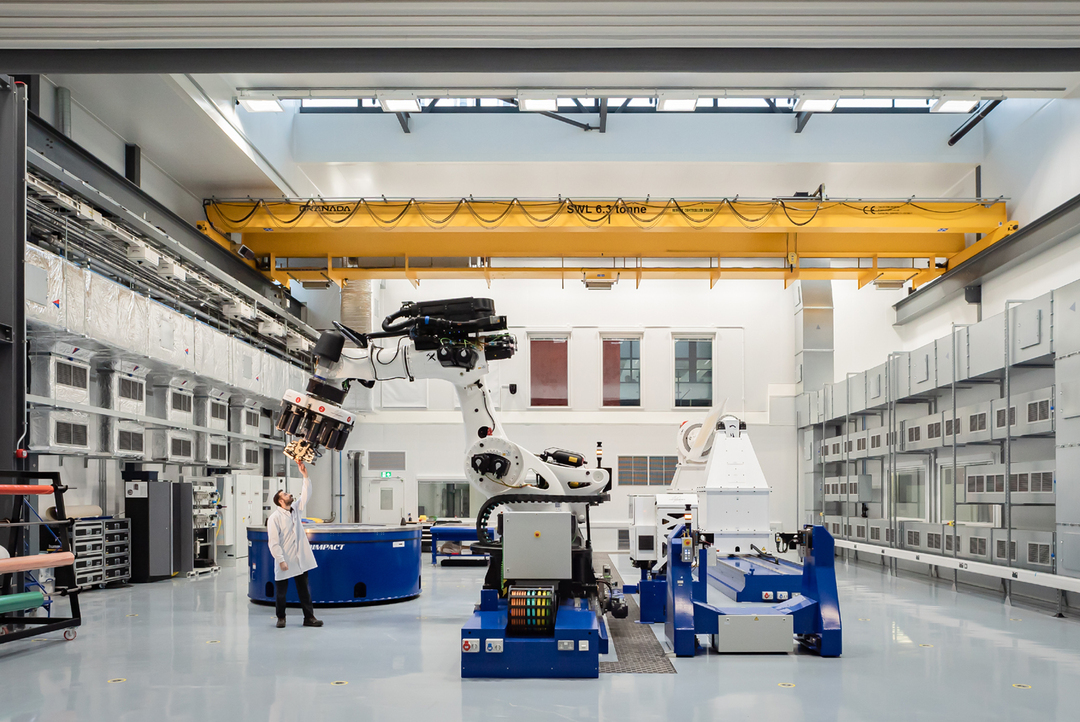

AFP Robot cell

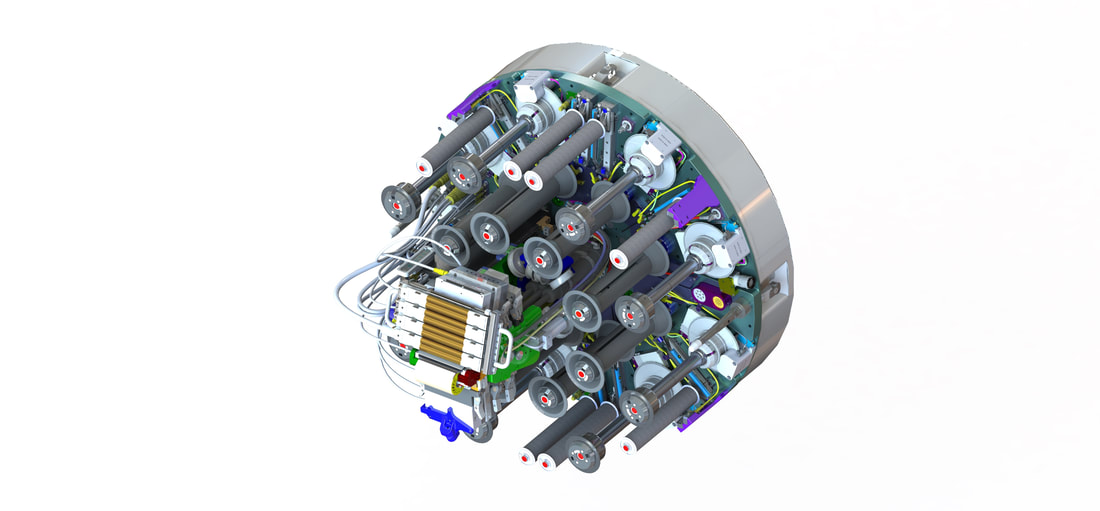

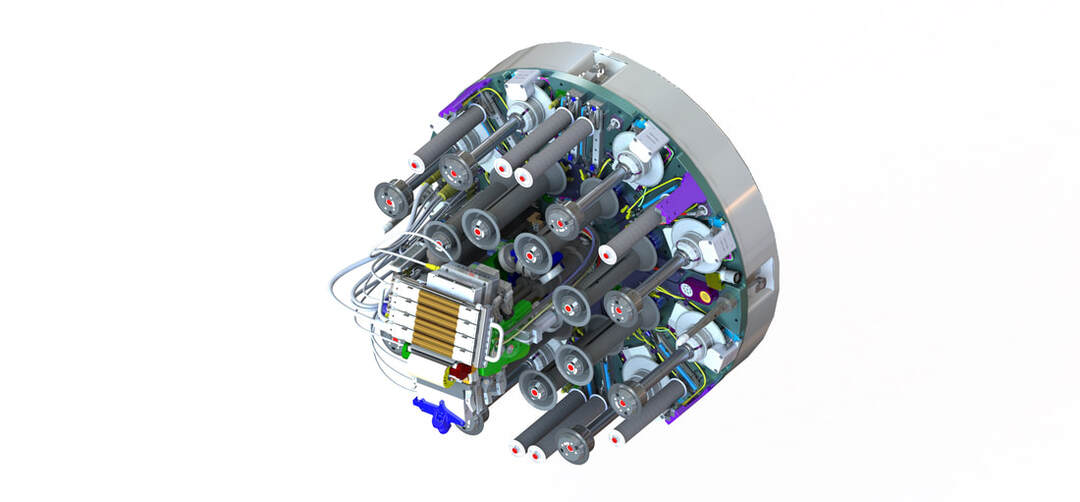

Because of each customer’s unique application, each new project involves a large amount of design changes to these heads. I lead a team of six engineers to create a new AFP head for the National Composite Centre (NCC) in Bristol, UK. This project involved adapting the widest format material (1/2”) to the smallest head format (8-spools) in order to fit the head inside a female tool. The NCC also required the integration of a xenon flash lamp heater in addition to a standard infrared heater.

Click here to start customizingIn order to meet these specifications we needed to design an almost completely new head. My team and I took advantage of this opportunity to correct many constraint problems and inconveniences which persisted on older AFP heads. After completion, these designs were quickly propagated to four new projects for other customers and have become a standard offering for Electroimpact.

AFP robot rotator demonstration

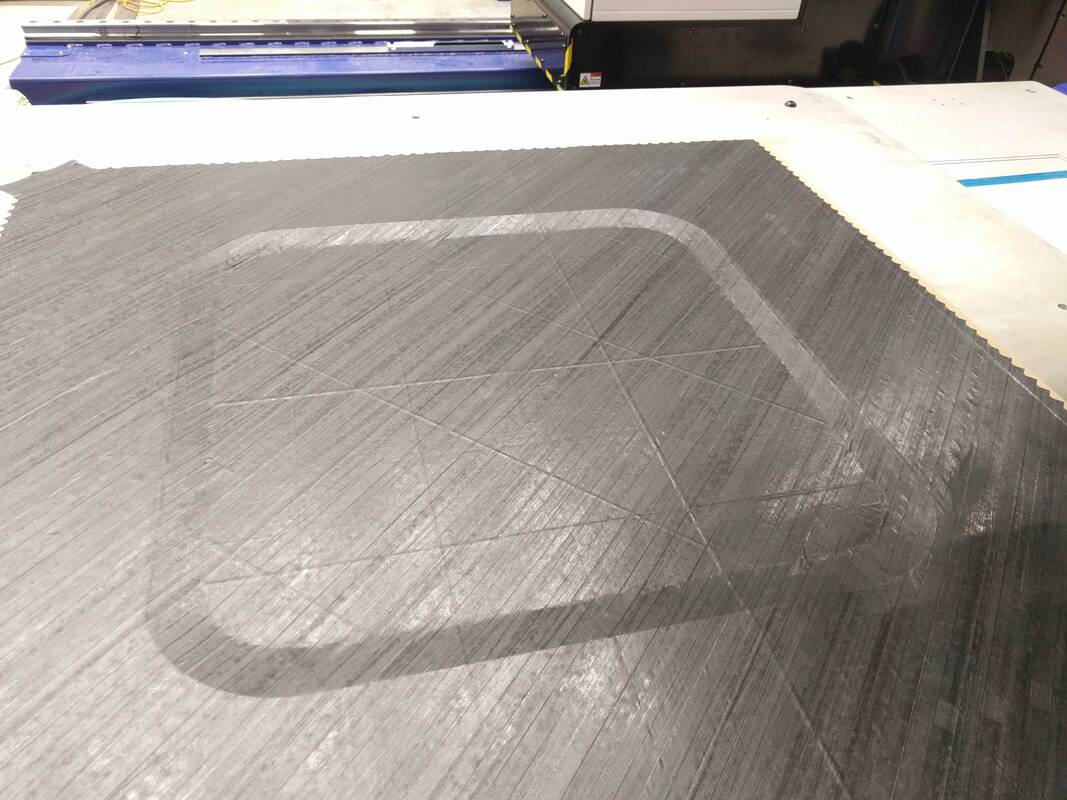

Carbon fiber tape layup

In addition to design work, I was responsible for some aspects of the construction and commissioning of AFP systems. Troubleshooting the problems seen on this equipment requires intimate knowledge of the mechanical, electrical, pneumatic, and controls systems and how they interact with each other. Through many cycles of design, testing, delivery and support I have learned how to better design for the whole life cycle of a product.

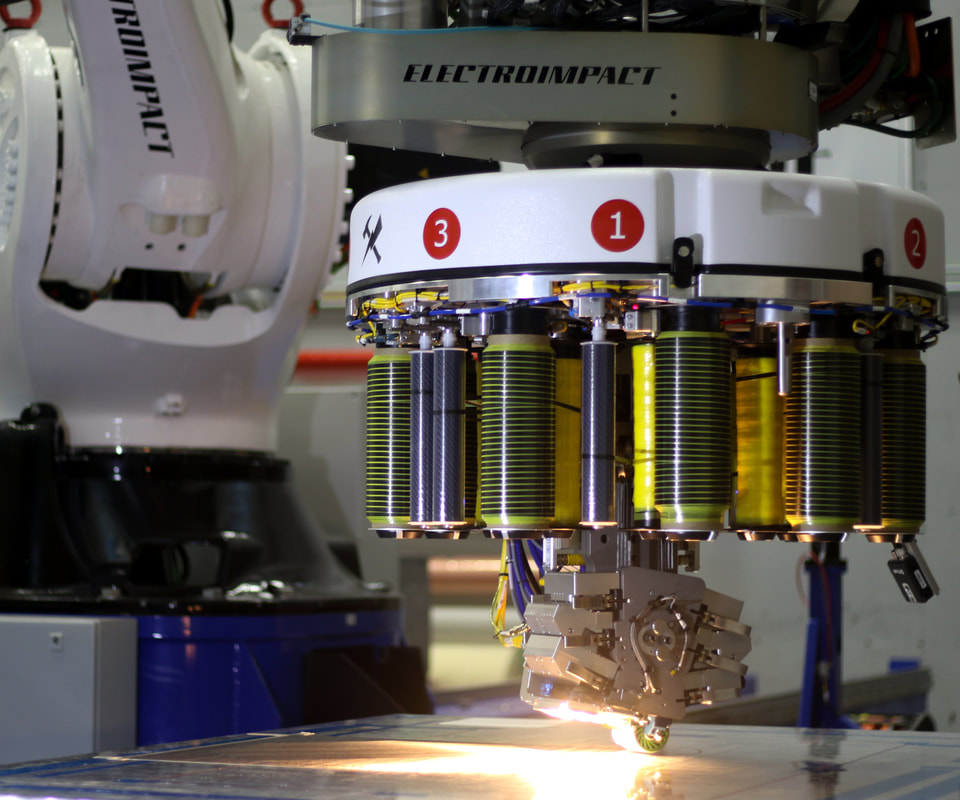

AFP head

AFP head CAD