One important feature of AFP systems is that the end effectors can be quickly placed into a stand and exchanged for a different end effector. Some of these stands move or rotate the end effector for operator or maintenance access.

I have designed several of these stands for different end effectors. In general, the stands consist of large steel weldments which are anchored into concrete. The weldments are built from tube steel and brake formed steel sheet. The sands need to repeatably locate the end effector for pickup and drop-off.

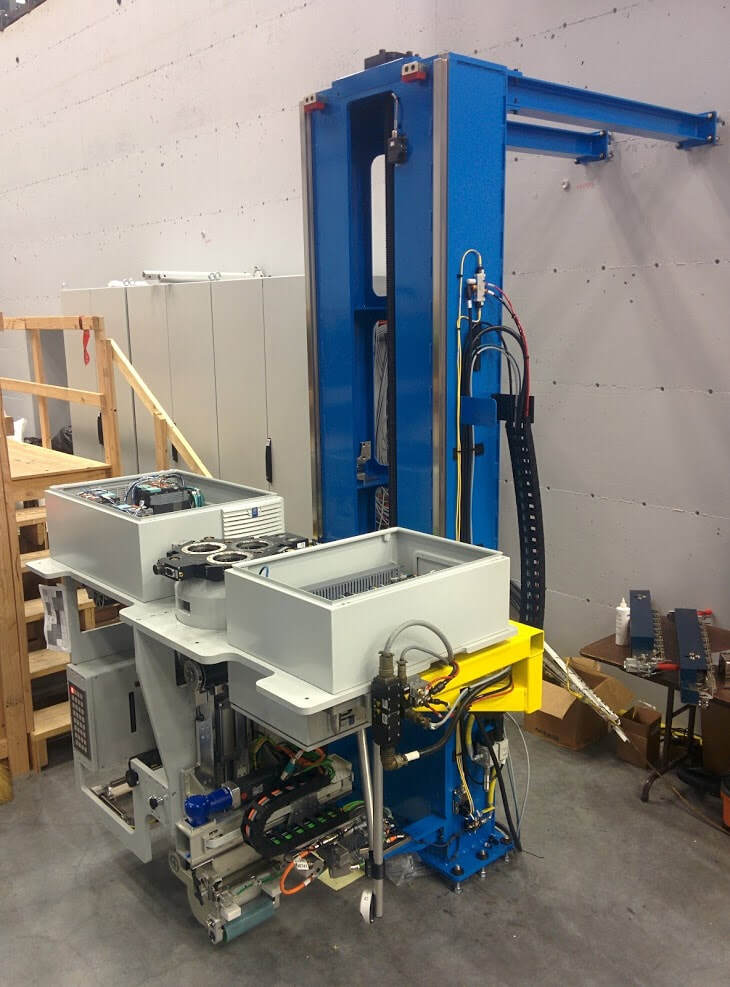

Equipment in lift

Lift with static stand

For one project I designed a stand which would lift a 1,500lb end effector to a position where it could be picked up by a gantry machine. My design uses a servo driven acme screw to lift the end effector. Linear rails and bearing cars were used for accurate and repeatable positioning. The structure was required to withstand a strong earthquake without falling over.

Cantilever stand

Two static stands with equipment