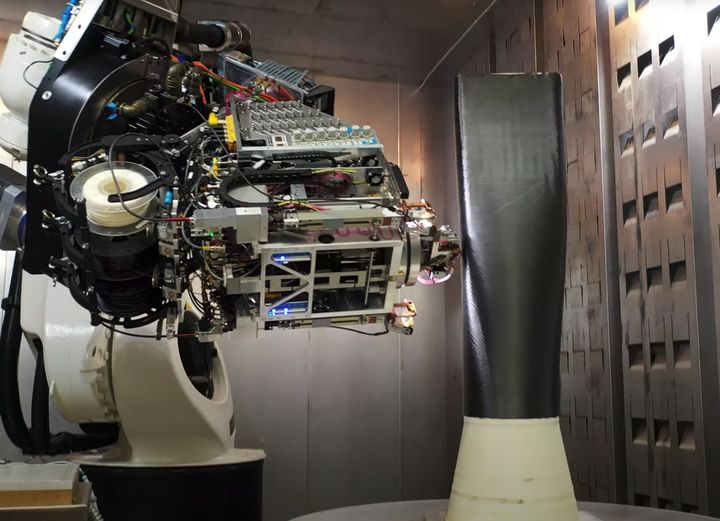

Electroimpact's Scalable Composites Robotic Additive Manufacturing (SCRAM) system is a true 6-axis continuous fiber reinforced 3D printer, enabling the tool-less rapid fabrication of aerospace-grade integrated composite structures. High-performance thermoplastics combined with a high percentage of continuous fiber reinforcement are used to produce parts with exceptional mechanical properties previously unheard of in the world of 3D printing.

The SCRAM system uses three separate process ends for building composite structures. Two of these are heated filament extruders, much like what you would see on a hobby 3d printer. The third is a tape laying system used to bond continuous fiber thermoplastic tape to the structure. Each of these processes requires a different material to be dispensed. An ABS-like material is used for printing a tool a tool that the composite structure will be build on. The other two materials are thermoplastics, one is a round filament for extruding and the other is a tape.

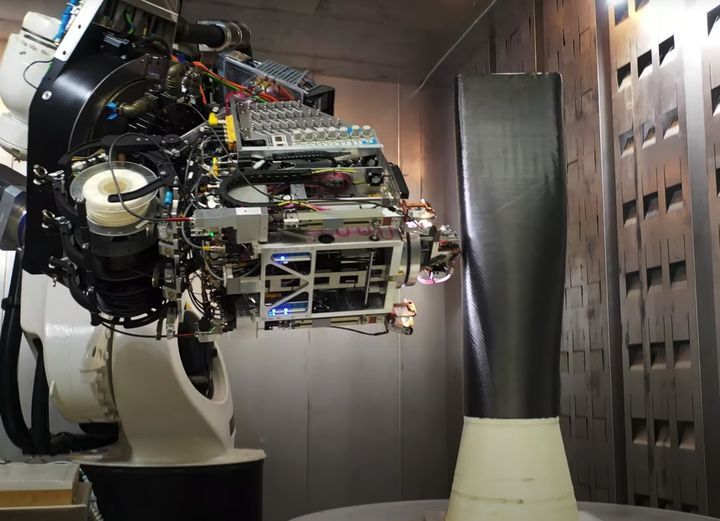

Example thermoplastic layup

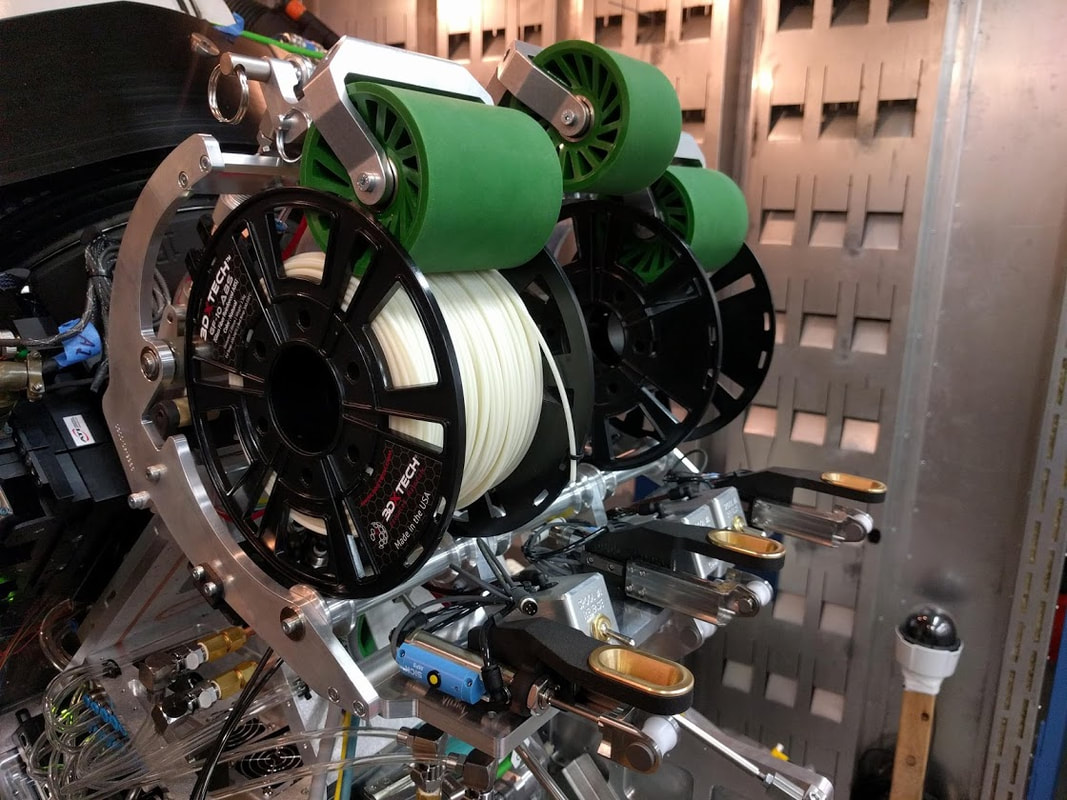

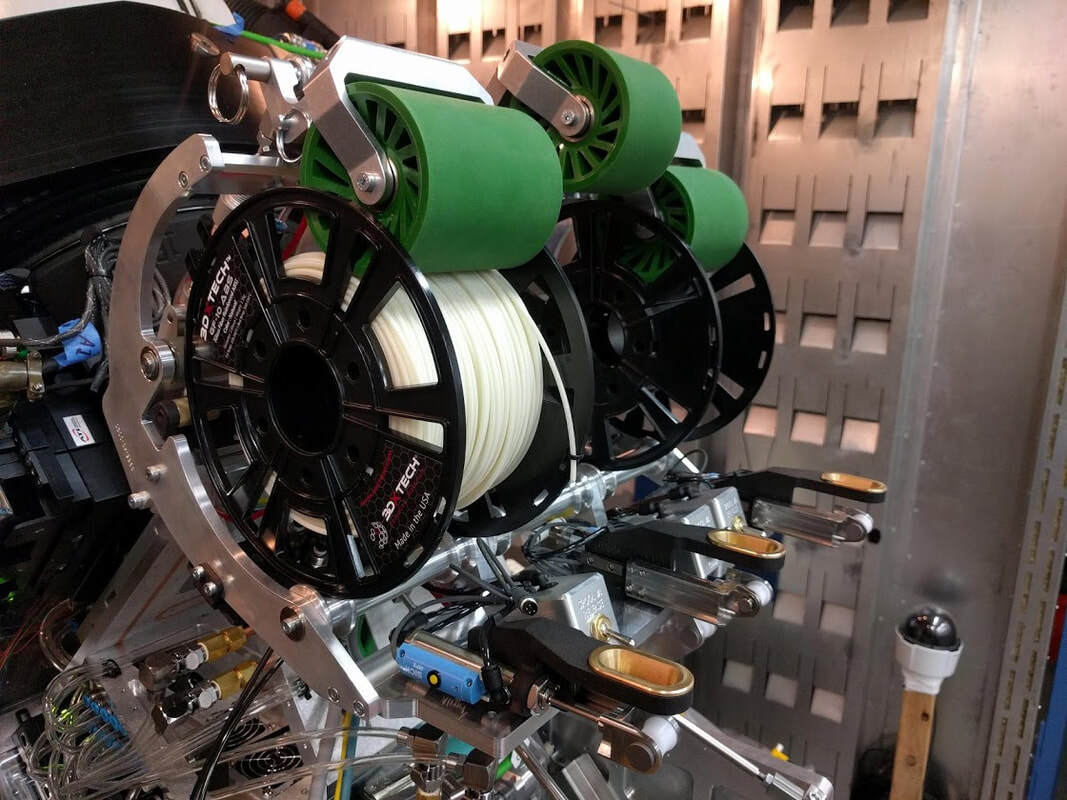

SCRAM material feed system

I designed a material storage and accurate feed system to meet the unique requirements of the SCRAM system. This assembly needed to mount onto the process end effector, store three different materials, be able to change material spools quickly, actively pay out the material, and select which material is to be dispensed.

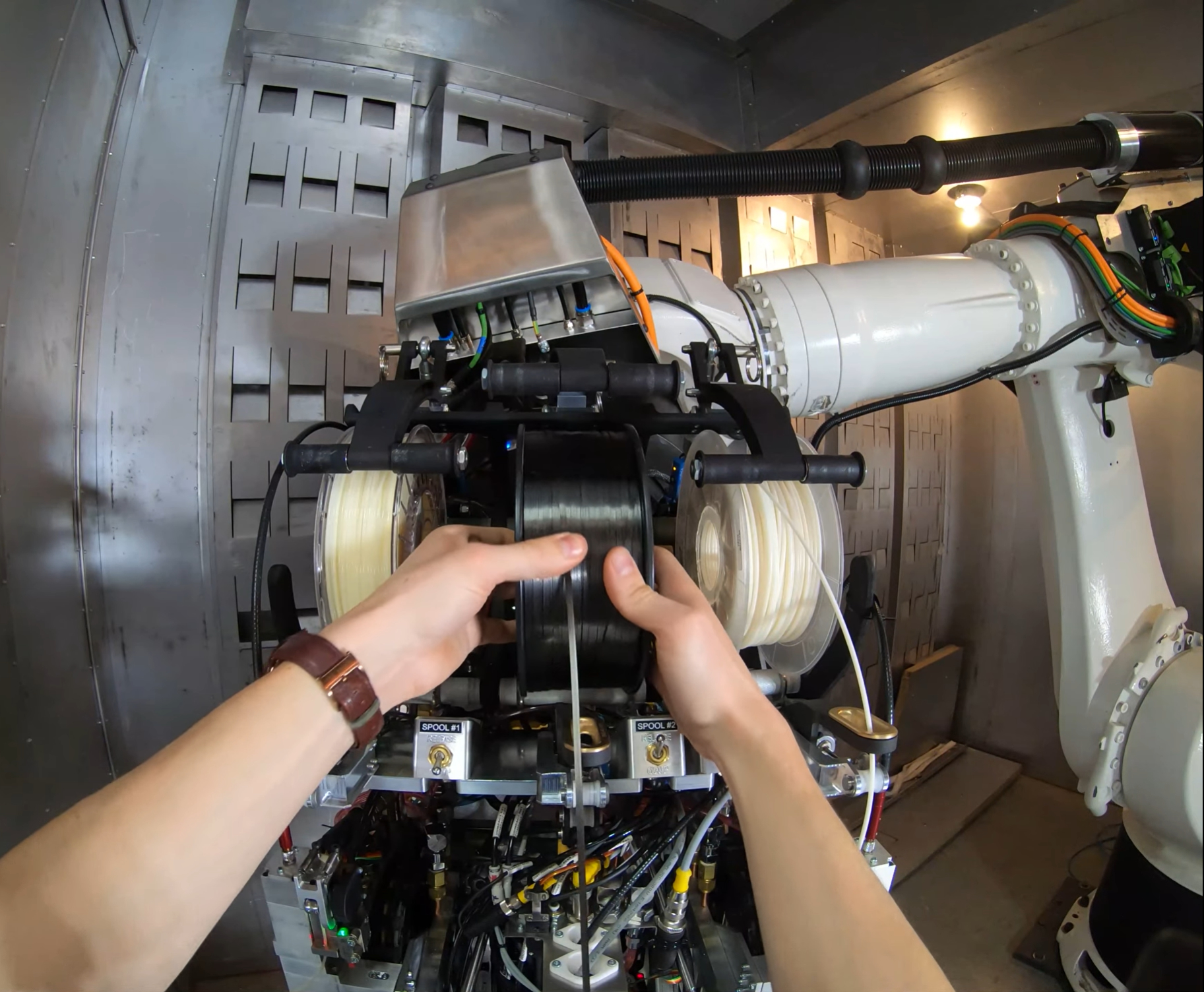

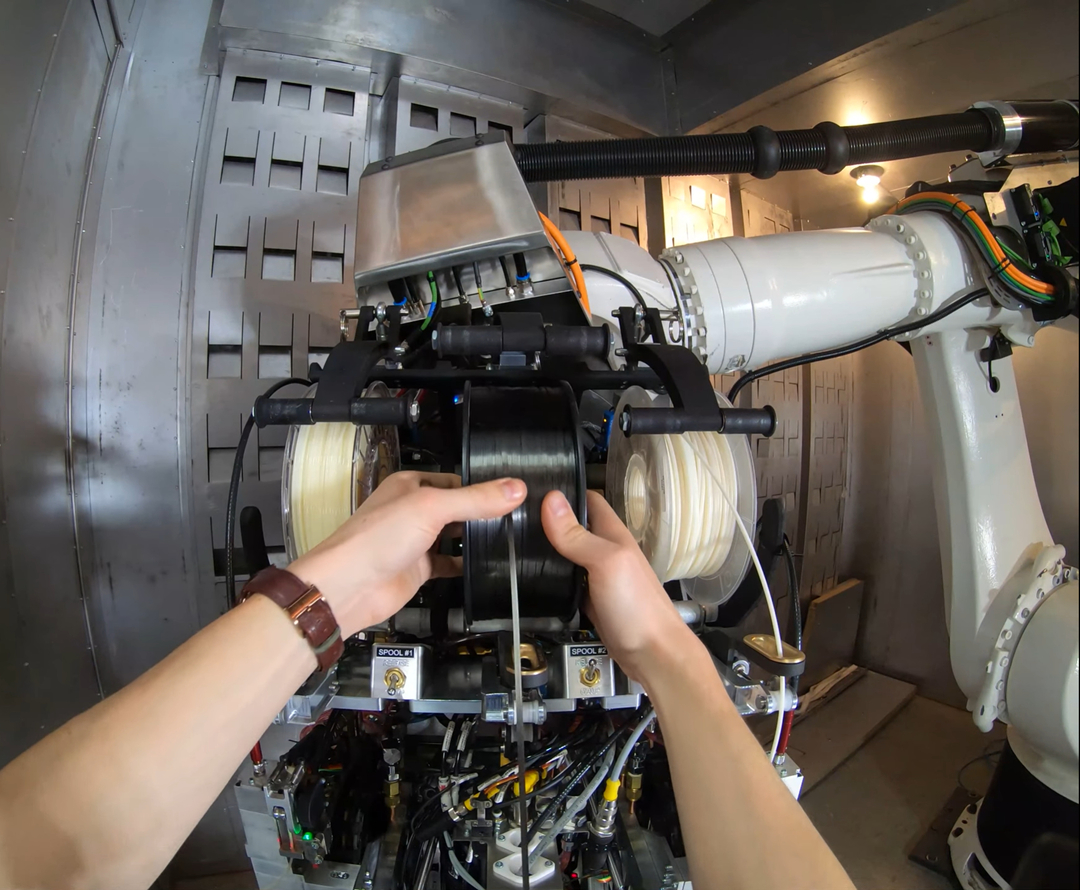

Being able to quickly change the materials was important to this project because the large aerospace structures that this system was designed to create require much more material than a typical 3d printer. While the spools of material resemble what you would see on a typical extrusion printer, they are widened to hold more material and still a single print will use several spools of material. On other printing systems these spools are often dispensed from some sort of shaft that runs through the center of the spool. having a center shaft would make removing and adding spools difficult. Instead, I designed a pneumatically driven arm an roller which secure the material in place and allow for the spools to be changed one at a time. The user toggles a pneumatic valve to select the position of the roller arm. The roller contacts the material itself to keep the spool wound tight during operation.

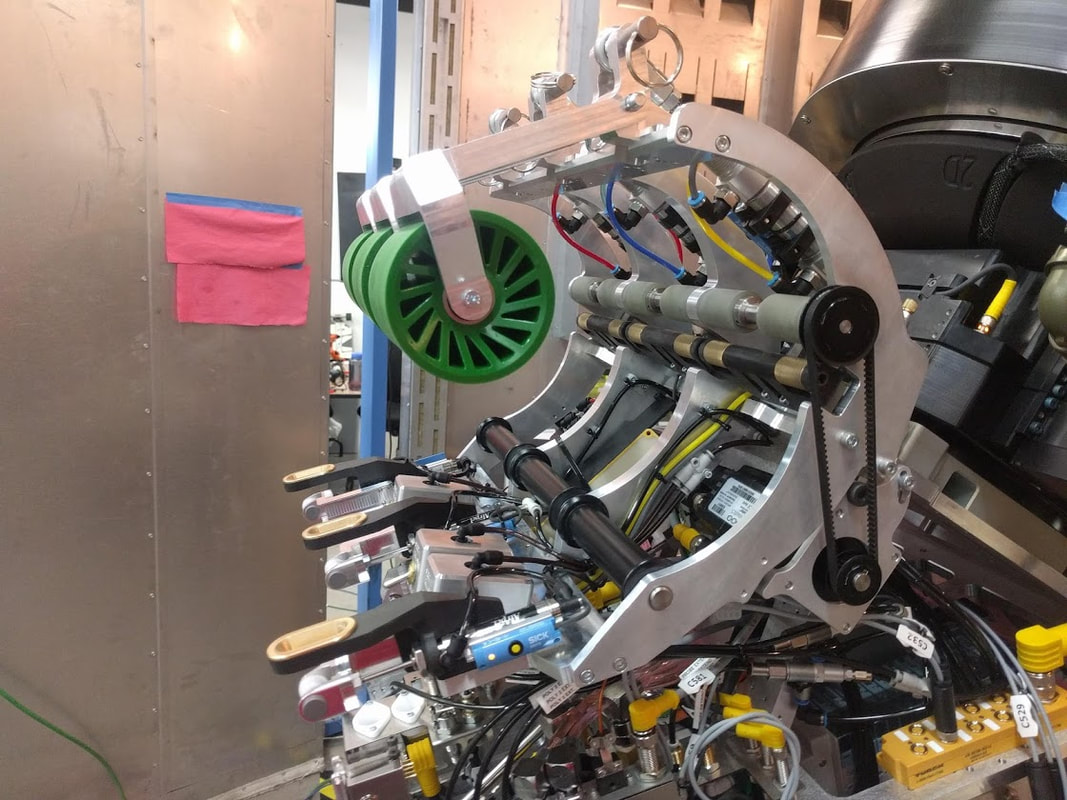

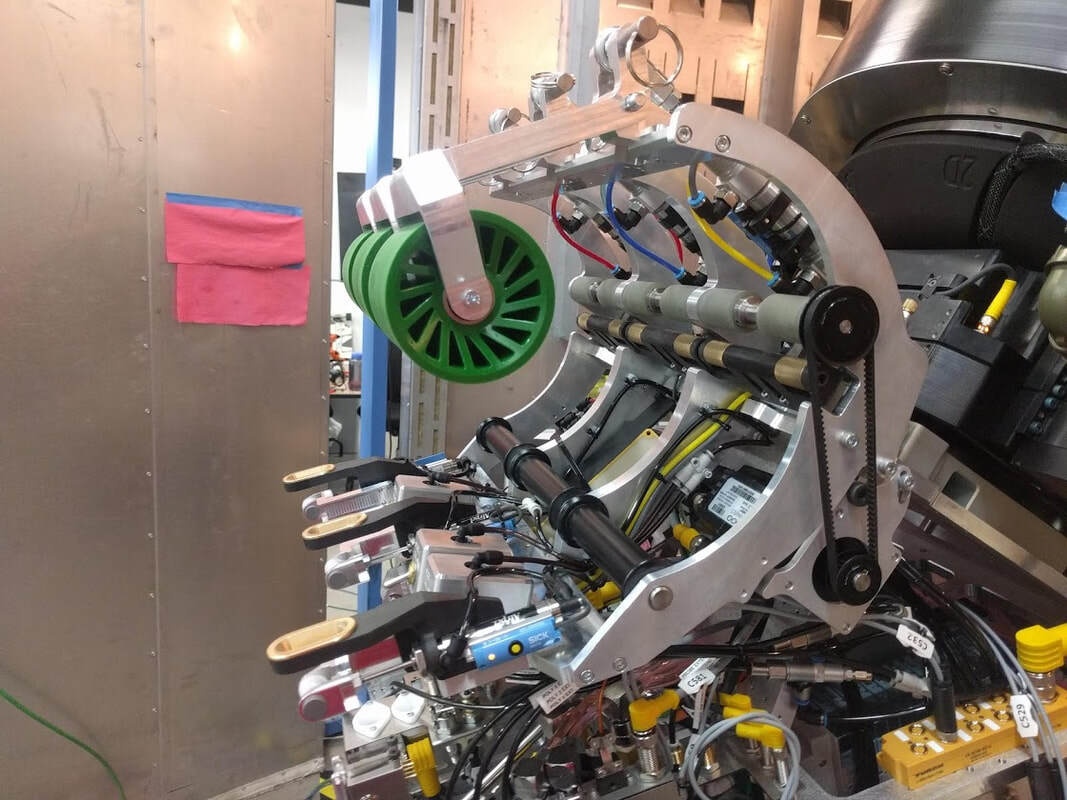

The material feed assembly must actively dispense the material as it is being used. During a print, only one material is used at a time and the other two are idle. I designed a method of dispensing only the chosen material using a single servo motor and three guided air cylinders. The servo motor turns a belt driven shaft that run along the back side of the three spools of material. The shaft has six urethane rollers which contact the rim of the material spools. Bellow the drive shaft are three guided air cylinders with brass rollers that can contact the rim of the spools when the cylinders are extended. Doing so pushes the spool off of drive shaft. The spool is able to move a small and still be securely held in place because the force of the selection cylinder can overcome the force of the roller arm. By extending two of the the selection cylinders and retracting the third, only one material spool contacts the drive shaft so that one can be dispensed.

Example thermoplastic layup

Material change operation

Side view, material feed assembly

When the SCRAM system is building a part, it must accurately dispense the correct quantity of material for each length of the toolpath. The process ends of the system have their own feed mechanisms which grip the material and drive it into the extruder or tape laying ends. It is possible to leave the spools of material free spinning and allow the process end feed to drag the material our of the spool. This creates reliability problems because the material is more likely to get jammed or slip due to added tension in the material.

I designed a feed system which is slaved to the process end feed by measurement of tension in the material. When it is time to dispense material the process end pulls on the material which increases tension in the line and will move a small air connected to a roller that touches the material. based on the position of that air cylinder the spool of material is advanced or reversed to keep consistent tension in the line. The video bellow shows this slave mechanism in action. It is hard to tell exactly what is happening in this video without some explanation. off-camera a person is pulling down on the material, or releasing the material. The small measurement air cylinder mentioned can bee seen towards the bottom of the frame. The spool of material rotates in both directions to either feed out or return the material to the spool.