The Automated Fiber Placement (AFP) heads and Kuka robots I worked with are controlled with Seimens PLCs, CNC, and a custom built HMI. As an engineer working on the development of the AFP heads, one of my responsibilities was to commission and test the entire AFP system before it was sent to the customer. This commissioning involved setup of the robot's CNC and PLC, setup of the head's PLC and integration of new equipment into the controls system.

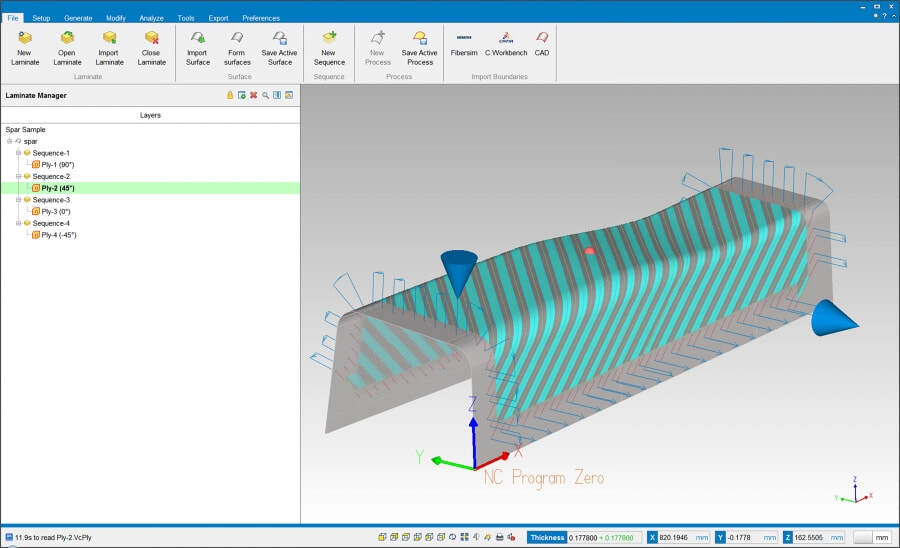

Composite layup path generation

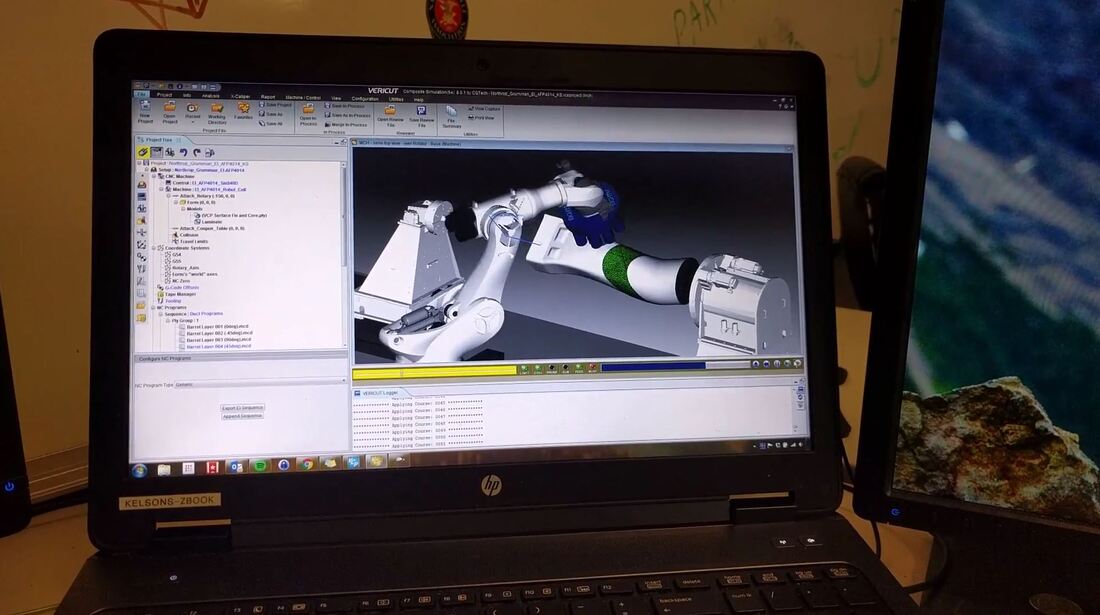

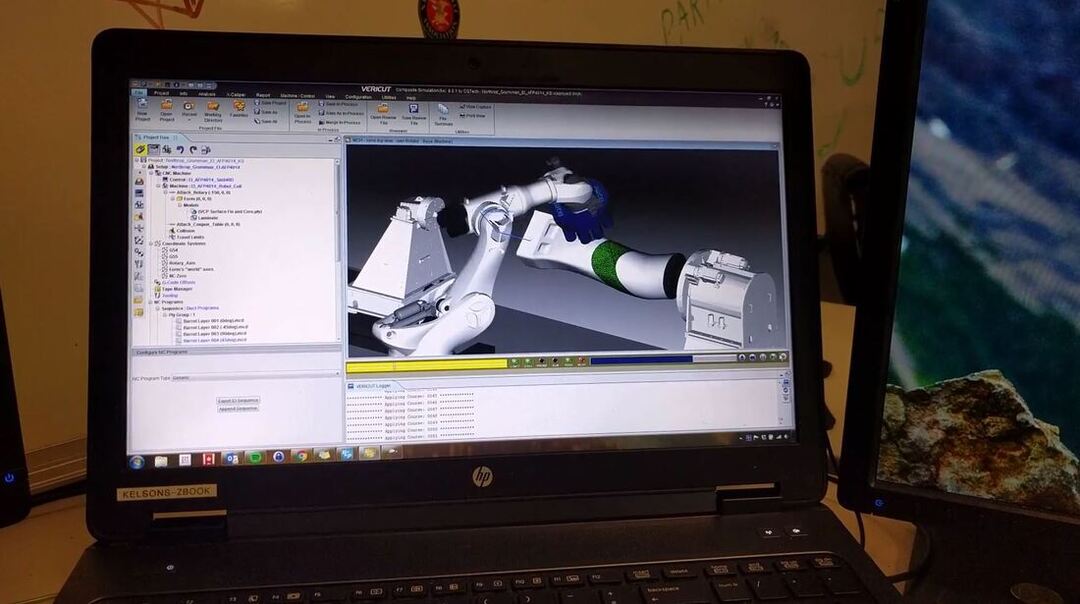

Motion simulation

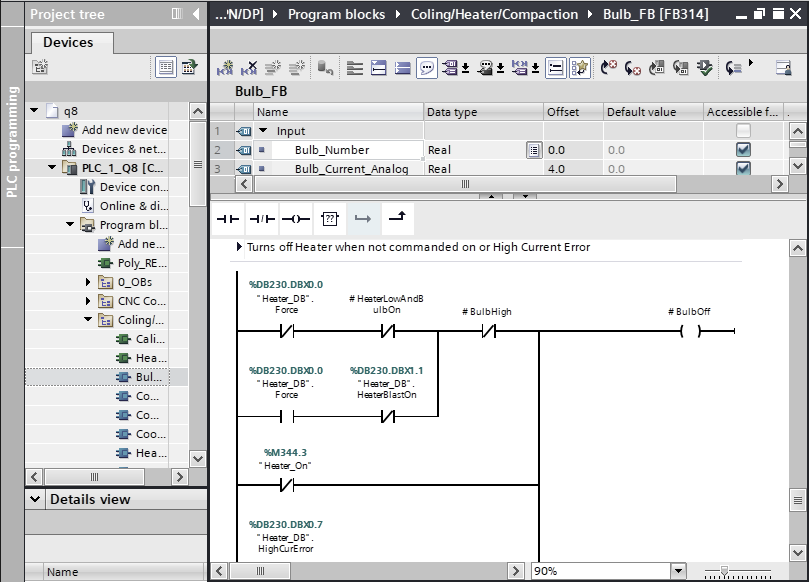

For example, one of the AFP heads I designed featured a new infrared heater design along with new current regulators to power the heater. To insure consistent heat was applied to the carbon fiber tape at a variety of different running speeds I had to characterize the heat output of the four separate infrared emitters. I did this by correlating the commanded power to the current regulators, to the temperature of the carbon fiber, measured with thermocouples, at a variety of different speeds. This experiment gave me the desired power command at each speed. With that knowledge I wrote a PLC function which controlled the heaters output based on the speed of the robots tool point.

PLC ladder program

Siemens plc inputs and outputs